Equalization tank

Technical description

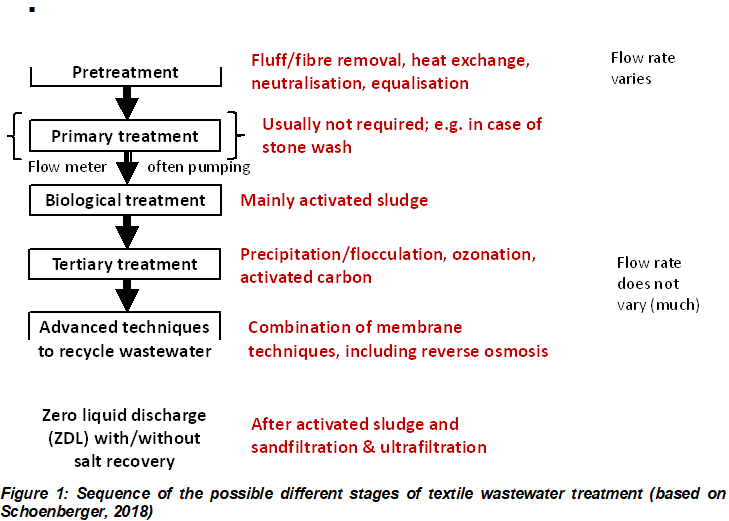

An equalization tank belongs to the first steps of textile wastewater treatment such as fibre removal, heat recovery, and neutralization. Figure 1 shows the whole possible sequence of textile wastewater treatment of which equalization is an important part of. The purpose of the equalization tank for industrial wastewater treatment is as follows (based on Eckenfelder, 2000):

- Dampening of organic load fluctuations to avoid shock loading on biological treatment system as well as to equalize the concentration of multiple organic and inorganic compounds in order to have a feed to biological treatment as constant as possible

- Minimizing flow surges to physical-chemical treatment systems

- Control pH or to minimize the chemical requirements for neutralization

- Even out the effect of a periodic ‘slug’ discharge from a batch process

- To provide continuous feed to biological systems over periods when the manufacturing plant is not operating

- Prevent peak values of toxic or inhibiting chemical compounds from entering the biological treatment stage.

Figure 1: Sequence of the possible different stages of textile wastewater treatment (based on Schoenberger, 2018)

The equalization of the flow is achieved by varying the wastewater level in the tank.

Figure 2 shows an example of an equalization tank prior to an activated sludge stage. The tank is aerated to enable optimized mixing and to avoid anaerobic conditions.

Achieved environmental benefits:

Flow and load equalization through an equalization tank is a method used to overcome the operational problems caused by flow rate variations to improve the performance of the treatment plants and to reduce the size and cost of downstream treatment facilities.

The principal benefits derived from the application of flow equalization are (I) biological treatment is enhanced, because shock loadings are eliminated or minimized, inhibiting substances are diluted, pH and temperature are counterbalanced; (2) the effluent quality and thickening performance of secondary sedimentation tanks following biological treatment is improved through stable food-to-microorganism ratio and the elimination of the flow surges; (3) effluent filtration, or other tertiary treatment systems, surface area or volumetric requirements are reduced, performance is improved, and (4) in chemical treatment, dampening of mass loading improves chemical feed control and process reliability. Apart from improving the performance of most treatment operations and processes, flow equalization also helps in improving the performance of overloaded treatment plants.

Operational data:

Type of Equalization Tank:

The equalization tank is a ‘variable inflow/constant discharge’ type. The influent flow is variable but the discharge flow or outflow is constant which is maintained and adjusted through the pump. The tank may have a rotating paddle for stirring or may be provided with coarse-bubble aeration from the bottom as an optional item if required by the nature of the wastewater. With all chemicals solubilized, which is often the case (no settable matter and no floating material such as pigment printing pastes or stones from stone washing operations), there is no sludge problem, otherwise, equipment for removing settable or floating materials has to be provided.

Equalization tanks may be of earthen, concrete, or steel construction; earthen basins are generally the least expensive. Depending on local conditions, the interior side slopes may vary between 3:1 and 2:1. In most installations, a liner is required to prevent groundwater contamination. Typically, for the textile wastewater, the water depth in the tank is within the range of 3.0 m to 4.5 m.

Equalization Tank Volume

The hydraulic volume of the equalization tank is the product of the average flow rate (m3/h) and retention time (h) or hydraulic retention time (HRT). The actual tank volume may be somewhat more, to account for a safety factor and free board as necessary. The retention time varies from 2 to 8 hours for industrial wastewater but may be even 12 hours (see Figure 2) or more in some cases. For textile industry wastewater, often retention time of 8 hours is often considered. With respect to subsequent biological treatment, it is of advantageous to have a one-day equalization, at least a half-a-day equalization.

Hydraulic volume of equalization tank = (x) m3/h x 8 h = (y) m3

Mixing and Air Requirement in the Tank:

The proper operation of the equalization tank generally requires proper mixing and aeration. Mixing and aeration are normally provided to ensure adequate equalization and to prevent settleable solids from depositing in the tank. Further, aeration is required to prevent the wastewater from becoming anaerobic which is associated with bad odours. The methods used for mixing and aeration include:

- Distribution of inlet flow and baffling

- Turbine mixing/mechanical aeration

- Diffused air aeration from the bottom

Most commonly submerged or surface aerators with power level of approximately 0.004 to 0.008 kW/m3 are used. To maintain aerobic conditions in the tank, air should be supplied at a rate of 0.01 to 0.015 m3/m3·min.

Figure 2 also shows an aerated equalization tank. The same is true for Figure 3 whereas Figure 4 just shows a scheme of an equalization tank.

Figure 3: View of Equalization Tank of a Textile Industry in Pakistan

Cross-media effects:

Solid waste generation in the form of removed settled sludge from the bottom of the tank during cleaning of the tank. The wastewater can become anaerobic and thus bad odors in case of malfunctioning of the mixing and aeration system of the tank can occur.

Technical considerations relevant to applicability:

Equalization tank is a very important component of the sequence of processes for textile wastewater treatment (see Figure 1). This component is an integral part of the wastewater treatment plant because the whole plant operation is based upon its optimum operation. It is important for the decision-makers in the textile industries for the selection and construction of wastewater treatment plants that the design parameters of the equalization tank should be evaluated apart from other considerations. In the case of an inappropriately designed tank and its operation, the efficiency of the whole treatment plant can be adversely affected.

The plant operator will require training for operating the wastewater treatment plant and the operation of the equalization tank from the technology vendor initially. The aeration requirement of the tank can be achieved through the air blowers already attached to the treatment plant.

Among the appurtenances that should be included in the design of the equalization tank are (I) facilities for flushing any solids and grease that may tend to accumulate on the tank walls, (2) an emergency overflow in case of pump failure, (3) arrangement for the removal of floating material and foam, and (4) always has a standby discharge pump.

The pump of appropriate capacity is required at the discharge side of the tank to discharge the contents of the tank into the treatment plant at a constant rate. The instrumentation (flow meter/flow control device) should be provided with the discharge pump to control the preselected equalization rate.

Economics:

Capital cost = USD 90,000 for locally constructed equalization tank (Pakistan)

Driving force for implementation:

The driving force for the installation of an equalization tank is to ensure the efficient operation of the whole wastewater treatment plant and achieve the desired quality of the effluent that complies with legal requirements.

Reference industry:

There are many textile finishing industries in Asia and other countries where wastewater treatment plants are installed and operating efficiently and equalization tanks are an integrated integral part.

References:

Eckenfelder Jr., W.W. (2000), Industrial Water Pollution Control, 3rd edition, McGraw-Hill Book

Schönberger, H., Technique combinations to meet the ambitious ZDHC Wastewater Guidelines, Proceedings of the Colloquium on Textile Wastewater Management 2018-09-18/Integrated Best Available Wastewater Management in the Textile Industry, Stuttgarter Berichte zur Siedlungswasserwirtschaft, Band 241, ISBN 978-3-8356-7411-0, Vulkan-Verlag GmbH, Essen (2018) 35 - 70

Back